Add to Cart

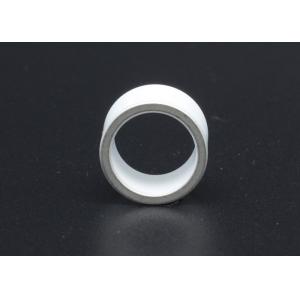

Magnetron Ceramic Rings With Metallized Layer

1. Description:

The magnetron series ceramics spare parts are produced by high purity alumina and metallization ways. It is suitable for brazing of different materials such as copper, aluminum, kovar and so on.

2. Key Words:

Magnetron, Microwave oven, Microwave generator, Radar microwave generator,uniform texture and good batch stability,dense, continuous, flat and weldable nickel layer,high flexural strength, high tensile strength and good air tightness,high frequency, high power and good safety components,Stable performance at high temperature circumstance,ceramic rings,microwave oven, microwave generator,high purity alumina.

3. Parameters:

| Product Parameters | ||

| Physical Property | Material | 95% Alumina |

| Production Process | Dry Pressing | |

| Product Dimension | Per customers' drawing | |

| Density (g/cm3) | 3.70-3.75g/cm3 | |

| Water Absorption | 0% | |

| Mechanical Performance | Flexural Strength (Mpa) | 310Mpa |

| Modulus of Elasticity (Gpa) | 310Gpa | |

| Hardness (Gpa) | 12.9Gpa | |

| Poisson Ratio | 0.23 | |

| Thermal Character | Linear Thermal Expansion Coefficient | 7.2 |

| Heat Conductivity (W/mk) | 23 | |

| Electrical Property | Dielectric Constant | 9.2 |

| Dielectric Loss Tangent (x10-4) | 8 | |

| Insulation Strength (x106V/M) | 15 | |

| Metalized Ceramic Performance | Air Tightness (Pa·m3/s) | ≤10-8 |

| Bulk Resistivity (Ω·cm) | ≥1010 (20°C), ≥106 (300°C) | |

| Bonding Strength (Mpa) | ≥120Mpa | |

| Metallization Thickness (μm) | ≥20μm | |